Service

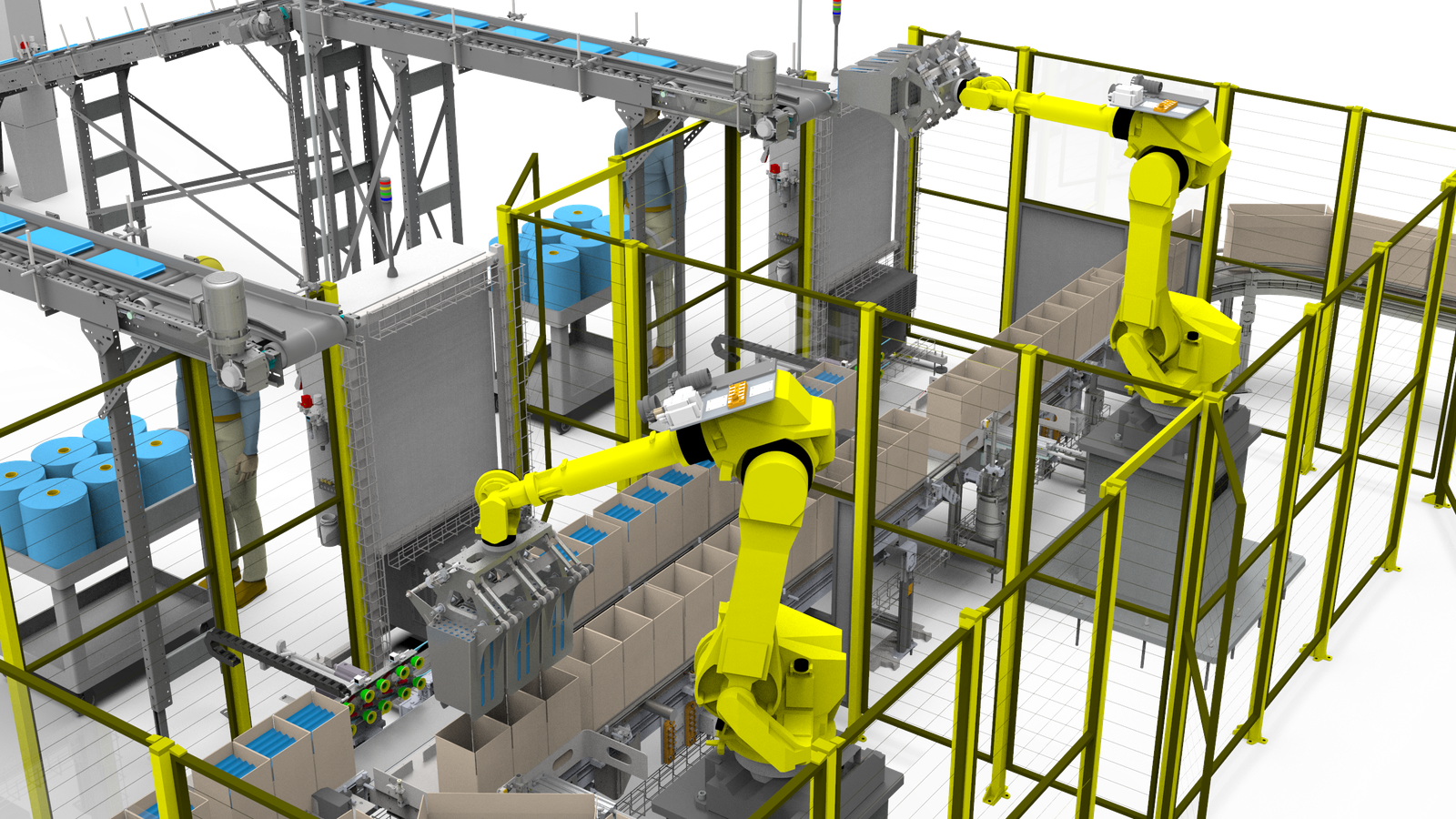

Automation system design and integration

In the dynamic landscape of modern manufacturing, the integration of automation systems has become indispensable for enhancing productivity, reducing costs, and ensuring competitiveness. The meticulous design and seamless integration of automation systems are pivotal in achieving these objectives. This comprehensive guide delves into the intricacies of automation system design and integration, outlining the standards, methodologies, and activities necessary for successful implementation.

What we do?

At AI Technologies, we specialize in the design and integration of automation systems tailored to meet the unique needs of modern manufacturing environments. Our mission is to enhance productivity, reduce operational costs, and ensure competitiveness through innovative automation solutions. We adhere to the highest standards and employ advanced methodologies to deliver seamless and effective automation systems.

Why choose us?

In the dynamic landscape of modern manufacturing, the integration of automation systems has become indispensable. Here’s why AI Technologies is the right choice for your automation needs:

- Expertise in Automation System Design and Integration:

- Thorough Analysis of Manufacturing Processes: We conduct detailed analyses of existing workflows to identify inefficiencies and opportunities for automation.

- Customized Automation Strategies: We develop tailored strategies that align with your organizational goals, ensuring optimal implementation.

- Robust Control Architecture: Our designs are based on industry standards and best practices, ensuring reliability and performance.

- Adherence to Industry Standards:

- We comply with standards like ISO 9001, Lean Manufacturing Principles, Six Sigma, IEC 61511, ISA-95, ASTM E2500, ISA-88, ANSI/ISA-95.00.01, and IEC 61131, ensuring quality and safety in all our projects.

- Collaborative Approach:

- We work closely with cross-functional teams to define objectives, conduct cost-benefit analyses, and develop implementation roadmaps.

- Comprehensive Services:

- From process walkthroughs and data analysis to functional specifications and risk assessments, we cover all aspects of automation system design and integration.

By choosing AI Technologies, you are partnering with a team dedicated to unlocking the full potential of automation, streamlining your production processes, and driving sustainable growth.

- Expertise in Automation System Design and Integration:

Conducting a Thorough Analysis of Manufacturing Processes

The foundation of any successful automation initiative lies in a comprehensive analysis of existing manufacturing processes. This involves scrutinizing each step of the production workflow to identify inefficiencies, bottlenecks, and areas ripe for automation. Several standards govern this analytical phase:

- ISO 9001: Quality Management Systems: This standard provides a framework for conducting process audits and identifying opportunities for improvement.

- Lean Manufacturing Principles: Concepts such as value stream mapping and waste reduction play a crucial role in pinpointing areas where automation can yield significant benefits.

- Six Sigma Methodology: Employing statistical analysis techniques can help quantify process variability and identify critical areas for optimization.

Activities:

- Conducting process walkthroughs and interviews with key stakeholders to gain insights into workflow dynamics.

- Utilizing data analytics tools to analyze historical production data and identify patterns of inefficiency.

- Performing time and motion studies to quantify the duration and frequency of manual tasks.

- Developing a Customized Automation Strategy

- Armed with insights from the analysis phase, the next step is to develop a tailored automation strategy aligned with organizational goals and objectives. Key standards and best practices in this phase include:

IEC 61511: Functional Safety of Safety Instrumented Systems for the Process Industry Sector: Ensuring the safety and reliability of automation systems is paramount, and compliance with this standard helps mitigate risks.

ISA-95: Integration of Enterprise and Control Systems: This standard provides guidelines for integrating automation systems with enterprise-level IT systems, enabling seamless data exchange and decision-making.

ASTM E2500: Standard Guide for Specification, Design, and Verification of Pharmaceutical and Biopharmaceutical Manufacturing Systems and Equipment: In regulated industries such as pharmaceuticals, adherence to standards like ASTM E2500 is essential for compliance and product quality assurance.

Activities:

- Collaborating with cross-functional teams to define automation objectives and success criteria.

- Conducting cost-benefit analyses to evaluate the economic feasibility of automation investments.

- Developing a roadmap for phased implementation, considering factors such as technology readiness and resource availability.

- Designing Control Architecture and Selecting Appropriate Components

The design phase involves translating the automation strategy into a robust control architecture and selecting suitable components to realize the envisioned system. Key standards and guidelines in this phase include:

ISA-88: Batch Control Standards: For industries involved in batch manufacturing, adherence to ISA-88 standards ensures consistency and repeatability in process control.

ANSI/ISA-95.00.01: Enterprise-Control System Integration: Applying the principles outlined in this standard facilitates seamless integration between control systems and higher-level enterprise systems.

IEC 61131: Programmable Controllers: This standard governs the programming languages and interfaces used in programmable logic controllers (PLCs), ensuring interoperability and ease of maintenance.

Activities:

- Developing functional specifications detailing the desired behavior of the automation system.

- Conducting risk assessments to identify potential hazards and implementing appropriate safety measures.

- Selecting control hardware and software components based on performance requirements, vendor reputation, and compatibility with existing systems.

Automation system design and integration represent a strategic imperative for modern manufacturing organizations seeking to remain competitive in a rapidly evolving landscape. By adhering to established standards, employing rigorous analysis methodologies, and executing meticulously planned activities, companies can unlock the full potential of automation to streamline production, enhance efficiency, and drive sustainable growth.