Services

PLC Programming, Design and Integration

In the realm of industrial automation, Programmable Logic Controllers (PLCs) serve as the backbone for controlling machinery and processes. The art of PLC programming entails writing, debugging, and refining code to automate tasks, enhance efficiency, and ensure seamless integration within manufacturing environments. This comprehensive guide explores the intricacies of PLC programming, elucidating the standards, methodologies, and activities essential for designing and integrating PLC systems effectively.

PLC Programming

The evolution of industrial automation has been closely intertwined with the development of Programmable Logic Controllers (PLCs). Originally conceived as replacements for hard-wired relay systems, PLCs have evolved into sophisticated control devices capable of orchestrating complex manufacturing processes with precision and efficiency. In modern manufacturing environments, PLC programming plays a pivotal role in realizing the full potential of automation systems.

1. Standards and Guidelines for PLC Programming

- The standardization of PLC programming languages and methodologies has been instrumental in promoting interoperability, reliability, and safety in industrial automation. The International Electrotechnical Commission (IEC) 61131 standardizes programming languages for PLCs, including Ladder Logic, Structured Text, Function Block Diagram, Sequential Function Chart, and Instruction List. These languages provide a common framework for expressing control logic, facilitating ease of programming and maintenance across different PLC platforms.

- Additionally, industry-specific standards such as ANSI/ISA-88 (Batch Control Standards) and ANSI/ISA-95 (Enterprise-Control System Integration) provide guidelines for designing and integrating PLC systems in various manufacturing contexts. Compliance with these standards ensures consistency in control strategies, data exchange protocols, and system interfaces, thereby enhancing interoperability and scalability.

- Safety standards also play a crucial role in PLC programming, particularly in industries where human safety is paramount. Standards such as ISO 13849 (Safety of Machinery – Safety-related Parts of Control Systems) and IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems) prescribe methods for assessing and mitigating risks associated with PLC-controlled machinery and processes. Adherence to these standards ensures that PLC systems are designed, implemented, and operated in a manner that minimizes the likelihood of accidents and injuries.

2. Writing and Debugging PLC Code

- PLC programming encompasses a variety of programming languages, each suited to different application scenarios and programming styles. Structured Text (ST) provides a high-level programming language reminiscent of traditional programming languages like C or Pascal, making it well-suited for complex algorithms and mathematical calculations. Ladder Logic, on the other hand, mimics the graphical representation of relay logic circuits, making it intuitive for electricians and technicians familiar with electrical schematics.

- Function Block Diagram (FBD) programming offers a graphical approach to representing control algorithms, with reusable function blocks representing logical operations or mathematical functions. Sequential Function Chart (SFC) programming allows for the visualization of control sequences as state-based diagrams, facilitating the design of sequential control logic.

- Regardless of the programming language chosen, adherence to best practices for code organization and documentation is essential for maintainability and troubleshooting. Well-commented code, meaningful variable names, and modular programming techniques contribute to code readability and facilitate rapid debugging and modification.

- Debugging PLC code requires a systematic approach, often involving the use of online monitoring tools provided by the PLC programming environment. These tools allow programmers to observe the execution of the code in real-time, monitor variable values, and diagnose errors or anomalies. Techniques such as breakpoint debugging, step-by-step execution, and variable watch windows are commonly used to identify and rectify issues in PLC programs.

3. Developing Logic Sequences for Automation

- The development of logic sequences for automation begins with a thorough understanding of the manufacturing process and the specific tasks to be automated. This may involve collaborating with process engineers, equipment operators, and other stakeholders to gather requirements and identify automation opportunities. Once the requirements are defined, the task of translating them into logical control sequences begins.

- In many cases, automation tasks can be modeled using state-based logic, where the system transitions between different states based on input conditions and internal variables. Sequential Function Chart (SFC) programming is particularly well-suited for representing such state-based logic, allowing programmers to define states, transitions, and actions in a structured manner.

- Error handling and fault tolerance mechanisms are integral components of logic sequences, ensuring that the system can respond appropriately to unexpected events or conditions. This may involve implementing alarm systems, emergency shutdown procedures, or fail-safe mechanisms to mitigate the impact of faults or errors.

- Simulating logic sequences using virtual PLC environments or simulation software is an essential step in the validation process. Simulation allows programmers to test the behavior of the control logic under different operating conditions, verify its correctness, and identify potential areas for optimization or improvement.

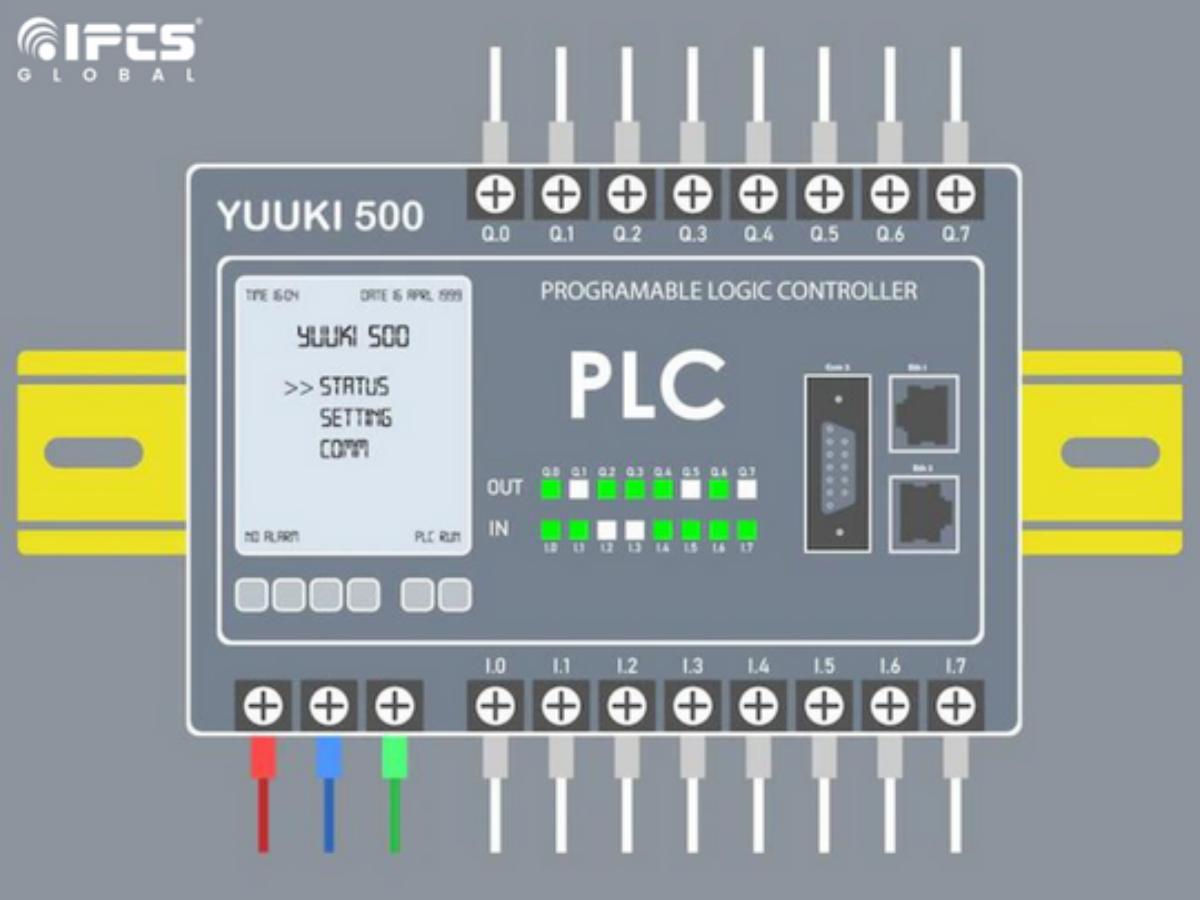

4. Integrating Multiple PLC Systems

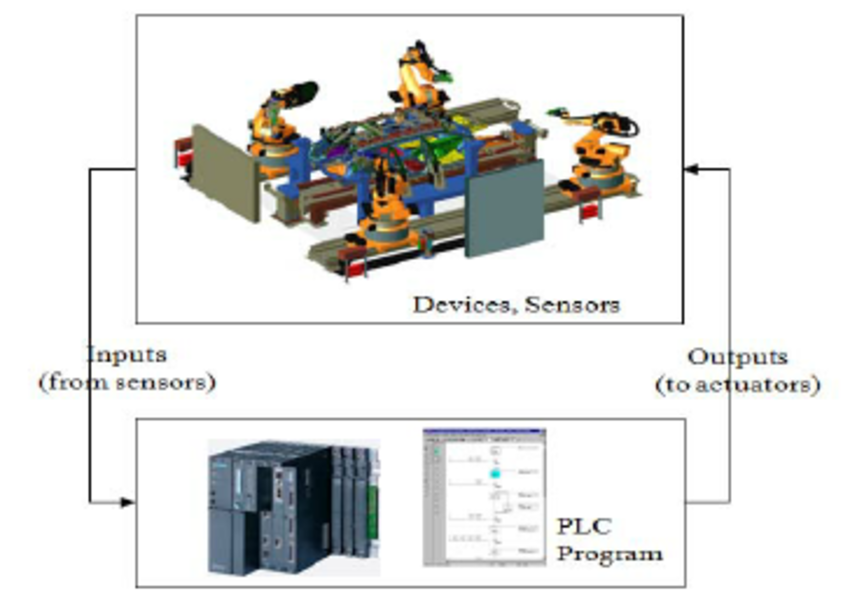

The integration of multiple PLC systems is a common requirement in complex manufacturing environments where multiple machines, processes, or production lines must work together seamlessly. This may involve interfacing PLCs with peripheral devices such as sensors, actuators, and human-machine interfaces (HMIs), as well as establishing communication channels between PLCs to enable data exchange and coordination.

Various communication protocols are used for PLC-to-PLC communication, including Ethernet/IP, Modbus TCP/IP, Profinet, and DeviceNet, among others. The choice of protocol depends on factors such as network topology, bandwidth requirements, and compatibility with existing systems.

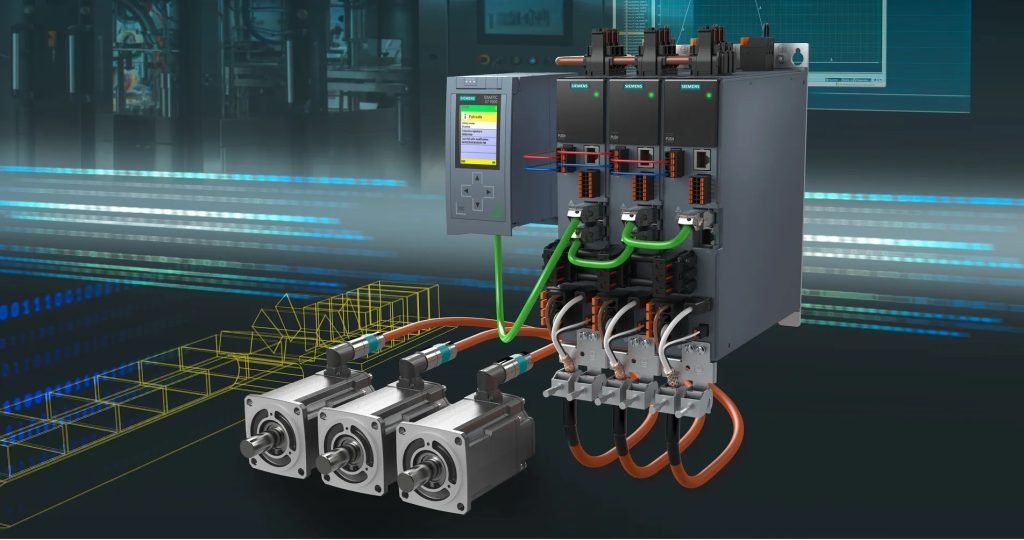

Synchronizing operations across multiple PLCs requires careful coordination of timing and sequence logic to ensure that each system performs its tasks in harmony with the others. This may involve implementing master-slave architectures, distributed control systems, or peer-to-peer communication schemes, depending on the application requirements.

Data exchange and sharing strategies are critical for enabling collaboration between PLC systems and higher-level control systems such as Supervisory Control and Data Acquisition (SCADA) or Manufacturing Execution Systems (MES). Standardized data formats, message protocols, and data mapping techniques facilitate seamless integration and interoperability between disparate systems.

Scalability and flexibility considerations are paramount when designing integrated PLC systems, as the system must be able to accommodate future expansion, upgrades, or modifications without requiring extensive rework. Modular architectures, standardized interfaces, and open-source technologies can help future-proof PLC systems and ensure their long-term viability.

Case Studies and Practical Applications

Real-world examples of PLC programming and integration illustrate the diverse range of applications and industries where PLCs play a central role in automation. Case studies may include:

- PLC programming for material handling systems, such as conveyor belts, robotic arms, and automated guided vehicles (AGVs), in warehouses, distribution centers, and manufacturing facilities.

- PLC integration in Manufacturing Execution Systems (MES) for real-time monitoring, control, and optimization of production processes, inventory management, and quality assurance.

- PLC-controlled robotics and automation cells for assembly, welding, packaging, and other manufacturing operations, demonstrating the versatility and precision of PLC-based automation.

- PLC applications in process industries such as chemical processing, pharmaceutical manufacturing, and food and beverage production, highlighting the challenges and opportunities unique to each sector.

By examining real-world examples, practitioners can gain insights into best practices, common pitfalls, and innovative solutions in PLC programming and integration.

Future Trends and Emerging Technologies

The field of PLC programming is continuously evolving in response to technological advancements, industry trends, and changing market dynamics. Key trends and emerging technologies shaping the future of PLC programming include:

- Industry 4.0 and Smart Manufacturing: The convergence of digital technologies such as IoT, AI, cloud computing, and big data analytics is driving the adoption of smart manufacturing concepts, where interconnected devices, intelligent algorithms, and data-driven insights enable autonomous, self-optimizing production systems.

- Edge Computing and IIoT Integration: Edge computing platforms bring processing power closer to the point of data generation, enabling real-time decision-making, reduced latency, and improved reliability in PLC-controlled systems. Integration with Industrial Internet of Things (IIoT) devices further enhances connectivity, visibility, and control across the manufacturing value chain.

- Artificial Intelligence and Machine Learning in PLC Programming: AI and machine learning techniques are increasingly being applied to PLC programming tasks, including predictive maintenance, anomaly detection, optimization, and adaptive control. AI-driven algorithms can analyze vast amounts of sensor data, identify patterns and correlations, and generate actionable insights to improve system performance and efficiency.

- Cybersecurity Considerations for PLC Systems: As PLCs become more interconnected and digitally integrated, cybersecurity threats pose a significant risk to industrial automation systems. Securing PLCs against malicious attacks, data breaches, and unauthorized access requires robust cybersecurity measures, including network segmentation, encryption, authentication, and intrusion detection systems.

PLC programming is a multifaceted discipline that requires a combination of technical expertise, domain knowledge, and problem-solving skills. By adhering to established standards and best practices, adopting a systematic approach to programming and integration, and staying abreast of emerging technologies and industry trends, practitioners can design and implement robust, reliable, and scalable PLC systems that drive operational excellence, innovation, and competitiveness.

Continuous learning and skill development are essential for staying relevant in the field of PLC programming, as technology advances and industry requirements evolve. Training programs, certifications, professional networks, and hands-on experience are valuable resources for enhancing proficiency and expanding knowledge in PLC programming and integration.

In conclusion, mastering PLC programming is not merely about writing code—it is about understanding the intricacies of industrial automation, solving complex engineering challenges, and leveraging technology to create smarter, more efficient, and more resilient manufacturing systems.